W201 M104 MS2 V3.0 Turbo

Re: W201 2.0 8V -> 2.8 24V MS2 V3.0

Mukava tämmöistä seurata, vaikkei oikeastaan ymmärrä muutakuin kuvat

Re: W201 2.0 8V -> 2.8 24V MS2 V3.0

Kiitoksia

Viime päivityksestä on jo hetki aikaa ja hallilla ei ole paljoa tapahtunut. Polttoainepumppu sanoi sopimuksen irti syyskuun puolivälissä ja tilalle tuli AEM polttoainepumppu (380 l/h@ 3 bar). Otin vanhan auki mielenkiinnosta ja tällaista löytyi:

Jokin on syönyt kuparia reilusti. Liekö ominaisuus etanolilla, tai sitten on ollut liian karkea suodatin.

Hiilissä olisi vielä pintaa.

Uuden pumpun myötä laitoin uuden suodattimen ja taas pelaa. Tankin tyhjennystä varten ei ollut mielenkiintoa ryömiä auton alle, joten tein niin, että laitoin tankin luukusta paineilmaa ja tulopuolen letkun kanisteriin. Onnistui yllättävän hyvin

Lisäsin myös Arduinoon 2 mosfettia (55NF06L), joita voi ohjata mm. CAN-väylästä saatavien moottorinohjaindatan perusteella. Yksi megan lähtö täytyy vapauttaa ahtopaineen ohjausta varten, koska siinä on valmiina PID-ohjaus ja käyttäjäystävällinen säätö (Tunerstudio). Siirrän todennäköisesti tuulettimen ohjauksen arduinon taakse. Kuvassa tuulettimen ohjauksen testausta, jossa polttimo on tuulettimen releen paikalla. 90°tuuletin menee päälle ja 87° se sammuu, koodi siihen:

Koodi: Valitse kaikki

void FanControl()

{

unsigned long FCcurrentMillis = millis(); // Record current time

if (FCcurrentMillis - FClastExecutedMillis >= FC_EXE_INTERVAL) //If elapsed time from last execution is more than the specified interval

{

FClastExecutedMillis = FCcurrentMillis;

if ((bCastMsg.clt-32)*5/9 >= 90 && FCstatus == 0)

{

digitalWrite(FCpin, HIGH);

Serial.println("Fan ON");

FCstatus = 1;

}

else if((bCastMsg.clt-32)*5/9 <= 87 && FCstatus == 1)

{

digitalWrite(FCpin, LOW);

Serial.println("Fan OFF");

FCstatus = 0;

}

Serial.println((bCastMsg.clt-32)*5/9);

}

}Siirsin lasinpesunestesäiliön takaluukkuun, jotta saan tilaa öljynkeruusäiliölle konehuoneeseen. Muutama kuva:

Letku ja johdot sukitettuna.

Aika hyvä siitä tuli. Kannakkeesta tuli ehkä rahtusen liian vahva, mutta kestänee kovaa ajoakin sitten. Luukussa oli valmiina aikanaan vetokoukkua varten laitetut vahvikepalat ja niiden pultit, joten uusia reikiä ei tarvinnut tehdä.

Aloin myös tekemään ilmanottoa kuntoon. 2,5 turbodieselin ilmansuodatinkotelo jo olikin, mutta paisuntasäiliö piti vaihtaa vielä kapeampaan, että se mahtuu. Paisuntasäiliön asennuksen jälkeen aloin hahmottelemaan pellistä ilmansuodatinkotelon kiinnitystä.

W124 turbon lokarista ritilä talteen.

Ritilä on vielä hitsaamatta kiinni W201 lokasuojaan, mutta pikkuhiljaa hyvä tulee.

Välijäähdytintäkin sovittelin keulalle, mahtuu hyvin puskurin alle. Zenderin puskurin leikkaaminen hieman hirvittää, mutta materiaa se vaan on.

To do lista tällä hetkellä:

- Korisarjan kiinnitykset kuntoon

- Ovien listojen kiinnitykset

- Ulkonäkö

- Takaikkunaa ympäröivien ruosteiden kiinniotto (ammattilaisella)

- (Ylimaalaus)

- Puskurien halkeamat kuntoon

- Antenni pois

- Käyntihäiriön korjaus (alipainevuoto?)

- Ahtaminen

- Turbon lokasuojan teko ja maalaus

- Ilmansuodatinkotelon sovittaminen ja kiinnitys

- Välijäähdyttimen sovittaminen ja kiinnitys

- Ahtoputket

- Turbon öljyn meno ja paluu

- Turbon veden meno ja paluu

- Konehuoneeseen tilaa -> Lasinpesunesteen säiliö luukkuun, uusi paisuntasäiliö

- Downpipen teko ja teippaus

- Hukkaportin asennus ja screamerin asennus tai hukkaportin laipan tukkiminen sarjasta

- "Väliseinä" ilmansuodatinkotelon ja moottorin väliin

- Imusarjan pituuden ohjaus pois (ahtoputkea varten)

- Huohotuksen uudelleenreititys

- Ahtopaineen ohjauksen asennus (venttiili ja johdotus)

Daily driver: Projekti, koska luotettavat autot ovat tylsiä Luotettava, eli tylsä CLK 270

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Re: W201 2.0 8V -> 2.8 24V MS2 V3.0

Päivitystä. Öljynkeruusäiliö saapui ja lähdin sille rakentamaan kannaketta, vähemmälläkin olisi varmaan päässyt, mutta halusin kokeilla miten pelti taipuu tahtoon

Tarpeeksi jykevä tuosta tuli ja painoa ei ole paljoakaan. Täytyy muistaa ottaa kuva kun on paikallaan, siihen menee hetki.

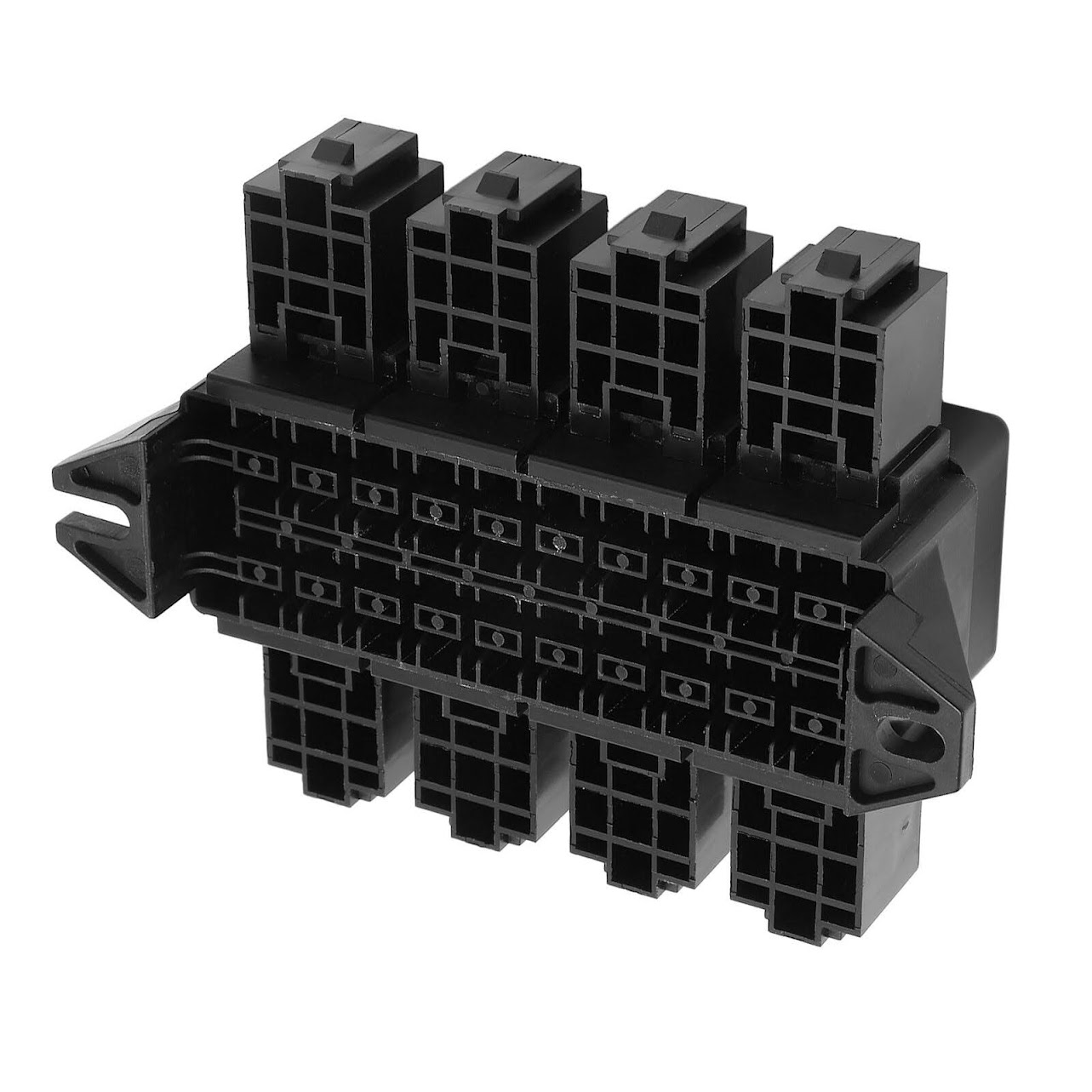

Sähköjä oli niin moneen kertaan jo vuosien varrella muutettu, että niitä oli aika jo vähän siistiä. Ostin tuollaisen 20 sulakkeen ja 8 releen pohjan ja lähdin rakentelemaan. Kuva: eBay

Valmiista tuotteesta ei ole vielä kuvaa, koska otin moottorin irti seuraavana. Siistimpi tuli kuitenkin, nyt yksi sulake/releboksi korvaa kaksi sulakeboksia ja yhden relepohjan, eli kolmesta käikäleestä mentiin yhteen.

Moottorin irroituksen jälkeen iski hinku sovittaa sarjaa paikalleen, koska uutta kiiltävää on aina hieno ihmetellä. No, kuinka kävikään, eihän tuo turbobanditin mallikohtainen (M104.94x) sarja sopinut edes paikalleen. Laipan pulttijako miten sattuu ja heitto kasvaa mitä pidemmälle laippaa mennään. Onneksi sentään siihen suuntaan, että lämmetessään laippa kasvaa oikeaan suuntaan. Muutamaa pultinreikää kun suurensi 13mm (10,8mm reiät alunperin muistaakseni), niin sai menemään paikalleen.

Näyttäähän se hyvältä, ei siinä. Neuvoja otetaan vastaan muuten siitä, että kannattaako tuo käydä pinnoittamassa. Downpipen teippaan termoteipillä joka tapauksessa ja laitan turbon hupun alle. Tuo M104 on kuitenkin sellainen vedenkeitin, että lämpöongelmaa on äkkiä varsinkin ahtaassa tenavan konehuoneessa. Pakosarjan keraamisella pinnoitteella saisi vähän lisää etumatkaa lämpöihin.

Ahtopaineen ohjauksesta: Ajattelin toteuttaa ohjauksen 4-tie venttiilin kanssa ulkoista hukkaporttia ohjaten, venttiilikin löytyi käytettynä Torista. Kuva: Full Race

Tällä ohjauksella ahtopaineet nousevat nopeammin ja teoriassa 0,8bar jousella voi saada ~3bar ahdot. Hukkaporttia pidetään ahtopaineella kiinni siihen asti kun tavoite on saavutettu, joka nopeuttaa ahtojen nousua. Yhtälailla ahtoja voi ohjata jousta myöden pienentäen ahtopainetta tietyllä kierrosalueella. Ongelmana 4-tieohjauksessa on resoluutio, eli pienet muutokset ohjauksessa voi tehdä isoja heittoja ahtopaineisiin. Katsotaan miten käy Lisää aiheesta Engine Basics

Lisää aiheesta Engine Basics

Muuten aiheeseen liittyvää, tilasin kansinahan, kansipultit ja muita tiivisteitä. Kansi menee jossain välissä koneistajalle ja samalla tulee uudet venttiilivarrenkumit ja venttiilit läpätään. Downpipeä, ahtimen pikkuhilppeitä ym. tarpeellisia varten on ostoskorit rakentumassa tarvikemotilla, KKD:llä ja do88:lla. Yritän saada sellaisen paketin, että ei tarvitsisi muuta kuin asentaa, saa nähdä miten käy. Ahtoputket (2,25") saapuivat ja vaikuttavat ihan hyviltä. Ainoana noottina se, että mustien silikonien sijaan lähettivät sellaiset, joissa ensimmäinen kerros on sinistä silikonia. En sinisestä silikonista välitä yhtään niin vähän alkoi nyppimään, mutta kenties niiden kanssa pystyy elämään?

Ahtamisen jälkeen avoin kela alkaa varmaan tökkimään, joten lukkojakin olen katsellut. Quaife olisi varmaan paras mahdollinen, mutta hinta hirvittää (1606,07€ kirjoitushetkellä, muutama vuosi sitten taisi olla luokkaa 1200€, joka kallis sekin). Kemppilukkoa tähän ei tule, joten siltä väliltä saattaisi joku tälläinen olla hyvä: https://racingdiffs.com/products/merced ... ersion-set

Ajatuksia lukoista otetaan vastaan myös. Onhan tuossa Kemppi hallilla, niin voi vaikka jonkun E36 perän sovittaa, mutta työläshän se olisi. Taitaisi mennä bensatankin sijaintikin uusiksi.

To do lista tällä hetkellä:

Tarpeeksi jykevä tuosta tuli ja painoa ei ole paljoakaan. Täytyy muistaa ottaa kuva kun on paikallaan, siihen menee hetki.

Sähköjä oli niin moneen kertaan jo vuosien varrella muutettu, että niitä oli aika jo vähän siistiä. Ostin tuollaisen 20 sulakkeen ja 8 releen pohjan ja lähdin rakentelemaan. Kuva: eBay

Valmiista tuotteesta ei ole vielä kuvaa, koska otin moottorin irti seuraavana. Siistimpi tuli kuitenkin, nyt yksi sulake/releboksi korvaa kaksi sulakeboksia ja yhden relepohjan, eli kolmesta käikäleestä mentiin yhteen.

Moottorin irroituksen jälkeen iski hinku sovittaa sarjaa paikalleen, koska uutta kiiltävää on aina hieno ihmetellä. No, kuinka kävikään, eihän tuo turbobanditin mallikohtainen (M104.94x) sarja sopinut edes paikalleen. Laipan pulttijako miten sattuu ja heitto kasvaa mitä pidemmälle laippaa mennään. Onneksi sentään siihen suuntaan, että lämmetessään laippa kasvaa oikeaan suuntaan. Muutamaa pultinreikää kun suurensi 13mm (10,8mm reiät alunperin muistaakseni), niin sai menemään paikalleen.

Näyttäähän se hyvältä, ei siinä. Neuvoja otetaan vastaan muuten siitä, että kannattaako tuo käydä pinnoittamassa. Downpipen teippaan termoteipillä joka tapauksessa ja laitan turbon hupun alle. Tuo M104 on kuitenkin sellainen vedenkeitin, että lämpöongelmaa on äkkiä varsinkin ahtaassa tenavan konehuoneessa. Pakosarjan keraamisella pinnoitteella saisi vähän lisää etumatkaa lämpöihin.

Ahtopaineen ohjauksesta: Ajattelin toteuttaa ohjauksen 4-tie venttiilin kanssa ulkoista hukkaporttia ohjaten, venttiilikin löytyi käytettynä Torista. Kuva: Full Race

Tällä ohjauksella ahtopaineet nousevat nopeammin ja teoriassa 0,8bar jousella voi saada ~3bar ahdot. Hukkaporttia pidetään ahtopaineella kiinni siihen asti kun tavoite on saavutettu, joka nopeuttaa ahtojen nousua. Yhtälailla ahtoja voi ohjata jousta myöden pienentäen ahtopainetta tietyllä kierrosalueella. Ongelmana 4-tieohjauksessa on resoluutio, eli pienet muutokset ohjauksessa voi tehdä isoja heittoja ahtopaineisiin. Katsotaan miten käy

Muuten aiheeseen liittyvää, tilasin kansinahan, kansipultit ja muita tiivisteitä. Kansi menee jossain välissä koneistajalle ja samalla tulee uudet venttiilivarrenkumit ja venttiilit läpätään. Downpipeä, ahtimen pikkuhilppeitä ym. tarpeellisia varten on ostoskorit rakentumassa tarvikemotilla, KKD:llä ja do88:lla. Yritän saada sellaisen paketin, että ei tarvitsisi muuta kuin asentaa, saa nähdä miten käy. Ahtoputket (2,25") saapuivat ja vaikuttavat ihan hyviltä. Ainoana noottina se, että mustien silikonien sijaan lähettivät sellaiset, joissa ensimmäinen kerros on sinistä silikonia. En sinisestä silikonista välitä yhtään niin vähän alkoi nyppimään, mutta kenties niiden kanssa pystyy elämään?

Ahtamisen jälkeen avoin kela alkaa varmaan tökkimään, joten lukkojakin olen katsellut. Quaife olisi varmaan paras mahdollinen, mutta hinta hirvittää (1606,07€ kirjoitushetkellä, muutama vuosi sitten taisi olla luokkaa 1200€, joka kallis sekin). Kemppilukkoa tähän ei tule, joten siltä väliltä saattaisi joku tälläinen olla hyvä: https://racingdiffs.com/products/merced ... ersion-set

Ajatuksia lukoista otetaan vastaan myös. Onhan tuossa Kemppi hallilla, niin voi vaikka jonkun E36 perän sovittaa, mutta työläshän se olisi. Taitaisi mennä bensatankin sijaintikin uusiksi.

To do lista tällä hetkellä:

- Korisarjan kiinnitykset kuntoon

- Ovien listojen kiinnitykset

- Ulkonäkö

- Takaikkunaa ympäröivien ruosteiden kiinniotto (ammattilaisella)

- (Ylimaalaus)

- Puskurien halkeamat kuntoon

- Antenni pois

- Konehuoneen maalaus/siistiminen

- Turbon lokasuojan teko ja maalaus

- Käyntihäiriön korjaus (alipainevuoto?)

- Ahtaminen

- Välijäähdyttimen sovittaminen ja kiinnitys

- Ahtoputket

- Turbo öljymeno suodatinjalasta M12 banjo

- Turbo öljynpaluun teko öljypohjaan

- Turbon veden meno ja paluu

- Downpipen teko ja teippaus

- Hukkaportin asennus ja reititys DP

- "Väliseinä" ilmansuodatinkotelon ja moottorin väliin

- Imusarjan pituuden ohjaus pois (ahtoputkea varten)

- Huohotuksen uudelleenreititys

- Ahtopaineen ohjauksen asennus (venttiili ja johdotus)

- Penkitys

- Muutoskatsastus

Viimeksi muokannut Mighty190, To 07.12.2023 09:07. Yhteensä muokattu 1 kertaa.

Daily driver: Projekti, koska luotettavat autot ovat tylsiä Luotettava, eli tylsä CLK 270

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Re: W201 2.0 8V -> 2.8 24V MS2 V3.0

Noi pilipala "lukot" kannattaa jättää sinne kauppaan, ei ne kestä edes talven suddailua saati sitten kesällä pitoja.

Kunnon lukko vaan kaupasta, kerran se kirpaisee ja on sitten sellainen että ei tarvitse joka hetki räplätä.

Pakosarja on hyvä pinnoittaa, auttaa lämpöjen kanssa ja ahtimen heräämiseen. Noista kiinan sarjoista sen verran että kannattaa ahdin tukea hyvin moottoriin, muuten pääset parsimaan halkeemia tämän tästä.

Kunnon lukko vaan kaupasta, kerran se kirpaisee ja on sitten sellainen että ei tarvitse joka hetki räplätä.

Pakosarja on hyvä pinnoittaa, auttaa lämpöjen kanssa ja ahtimen heräämiseen. Noista kiinan sarjoista sen verran että kannattaa ahdin tukea hyvin moottoriin, muuten pääset parsimaan halkeemia tämän tästä.

Re: W201 2.0 8V -> 2.8 24V MS2 V3.0

Näinhän se on tuon lukon kanssa, ei sitä perää jaksa joka viikko pöydälle nostaa. Täytyy tutkailla vaihtoehtoja. Vaikka pakosarjan sopivuus on kiinan sarjan luokkaa, niin tuo on ihan turbobanditin valmistama. Ajattelin ostaa kunnollisen ja kuinka kävikäänMJPfin kirjoitti: ↑Ke 06.12.2023 12:00 Noi pilipala "lukot" kannattaa jättää sinne kauppaan, ei ne kestä edes talven suddailua saati sitten kesällä pitoja.

Kunnon lukko vaan kaupasta, kerran se kirpaisee ja on sitten sellainen että ei tarvitse joka hetki räplätä.

Pakosarja on hyvä pinnoittaa, auttaa lämpöjen kanssa ja ahtimen heräämiseen. Noista kiinan sarjoista sen verran että kannattaa ahdin tukea hyvin moottoriin, muuten pääset parsimaan halkeemia tämän tästä.

Daily driver: Projekti, koska luotettavat autot ovat tylsiä Luotettava, eli tylsä CLK 270

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Re: W201 2.0 8V -> 2.8 24V MS2 V3.0

No varmaksi en sano mutta näyttää tasan identtiseltä saumat laipat ym kiina sarjojen kanssa. Ettei vaan ole työnnetty kiinaan tilaus että tämmöisiä. Istuvuus tukisi tätä väitettä.

Re: W201 2.0 8V -> 2.8 24V MS2 V3.0

Tiedä sitten. Varmaa on se, että toista kertaa en sieltä sarjoja osta.

Daily driver: Projekti, koska luotettavat autot ovat tylsiä Luotettava, eli tylsä CLK 270

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Re: W201 2.0 8V -> 2.8 24V MS2 V3.0

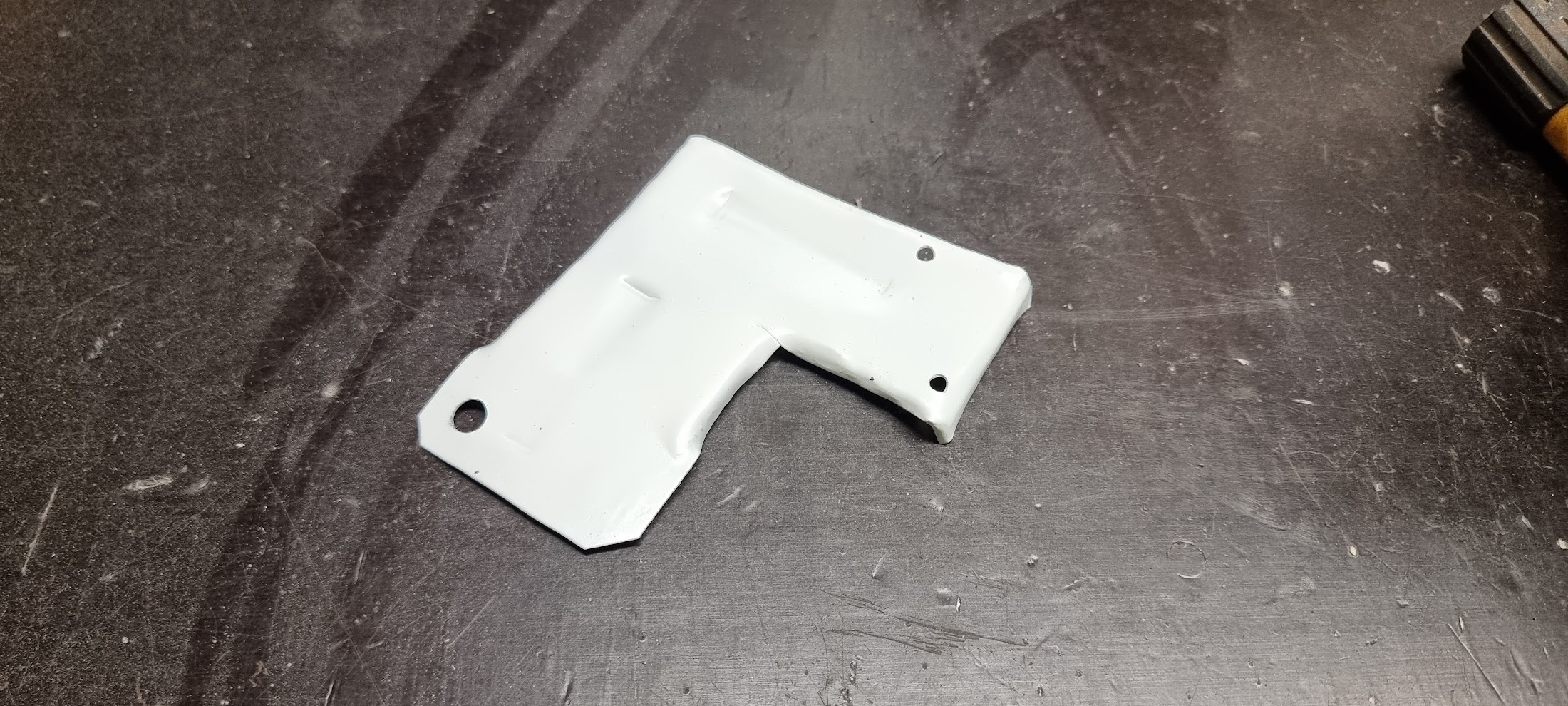

Jatkoa. Lähdin tekemään lokasuojaa:

Käristysvaiheessa ei ollut sen suurempia ongelmia. Kittauksen jälkeen ongelmia alkoi syntymään. Olen joskus (2015?) maalannut tuon lokasuojan ja siinä väri on halkeillut syystä x. Hioin siitä mielestäni tarpeeksi, mutta kuvat puhukoot puolestaan.

Hiontaväriksi tuo kerros oli tarkoitettukin, mutta tuo kiehuminen/reaktio yllätti. Kokeilin vielä kerran hierasta ja vähän vielä senkin jälkeen reagoi. Lopulta vein puhallettavaksi ja maalari saa hoitaa tästä eteenpäin Ehkä tuo hitsaus oli tarpeeksi DIY, että maalauksen voi ulkoistaa. Samalla vein venttiilikopan maalarille, että olisi joku helppokin homma.

Ehkä tuo hitsaus oli tarpeeksi DIY, että maalauksen voi ulkoistaa. Samalla vein venttiilikopan maalarille, että olisi joku helppokin homma.

Samassa tilassa on toki pohjatöiden jälkeen hyvä avata kansi, joten niihin puuhiin siirryinkin seuraavaksi. Kone yläkuolonkohtaan, merkinnät rattaisiin ja kansi irti. Kansipulttien venymistä en vielä mitannut, uudet on joka tapauksessa tulossa.

Nokkia irrottaessa ei ollut muuta huomionarvoista kuin se, että 5. sylinterin etummaisen imuventtiilin nostajakuppi oli vähän ottanut itseensä.

Ehjä vertailuksi.

Nokka-akselissa on pientä jälkeä, mutta koneistajan lausunnon perusteella menee vielä (kymmenyksen heitto).

Kansi lihalaatikkoon ja koneistajalle. Kansi ajetaan tasoon ja venttiilivarren kumit vaihdetaan samalla. Öljynsuodatinjalkaan tehdään myös 10mm banjolähtö.

Tarvikemotista tuli sälää:

Tuolla sai turbon lähdön kolmituumaiseksi ja sisäisen hukkiksen pois. DP on noin metrin 3" ja jatkuu 2,5" perälle asti. Sitten kun kansi ja venakoppa tulee, niin pääsee kasaamaan. Pakosarja on vielä pinnoitettavana, joten sitä saa odotella. Öljynpaluun voisi tehdä öljypohjaan, mutta hölmönä otin moottoripukin lainaan vasta kannen irroituksen jälkeen (ei oikeen voi nostaa pukille). Täytynee odottaa kantta ja sen asennusta siis ennen öljypaluun tekoa. Ostin läpipultattavan mallin, ehdotuksia otetaan vastaan jostain öljynkestävästä kierrelukitteesta.

To do lista tällä hetkellä:

Käristysvaiheessa ei ollut sen suurempia ongelmia. Kittauksen jälkeen ongelmia alkoi syntymään. Olen joskus (2015?) maalannut tuon lokasuojan ja siinä väri on halkeillut syystä x. Hioin siitä mielestäni tarpeeksi, mutta kuvat puhukoot puolestaan.

Hiontaväriksi tuo kerros oli tarkoitettukin, mutta tuo kiehuminen/reaktio yllätti. Kokeilin vielä kerran hierasta ja vähän vielä senkin jälkeen reagoi. Lopulta vein puhallettavaksi ja maalari saa hoitaa tästä eteenpäin

Samassa tilassa on toki pohjatöiden jälkeen hyvä avata kansi, joten niihin puuhiin siirryinkin seuraavaksi. Kone yläkuolonkohtaan, merkinnät rattaisiin ja kansi irti. Kansipulttien venymistä en vielä mitannut, uudet on joka tapauksessa tulossa.

Nokkia irrottaessa ei ollut muuta huomionarvoista kuin se, että 5. sylinterin etummaisen imuventtiilin nostajakuppi oli vähän ottanut itseensä.

Ehjä vertailuksi.

Nokka-akselissa on pientä jälkeä, mutta koneistajan lausunnon perusteella menee vielä (kymmenyksen heitto).

Kansi lihalaatikkoon ja koneistajalle. Kansi ajetaan tasoon ja venttiilivarren kumit vaihdetaan samalla. Öljynsuodatinjalkaan tehdään myös 10mm banjolähtö.

Tarvikemotista tuli sälää:

- 3" RST-putkea ja mutkaa

- Termoteippiä

- Turbon huppu

- DP-laippa-adapteri

- Öljynpaluusarja

- Öljynpaineletku

- Pinnapultit, kuparimutterit, V-pantasarja, imuilman lämpötila-anturi ja muuta pientä

Tuolla sai turbon lähdön kolmituumaiseksi ja sisäisen hukkiksen pois. DP on noin metrin 3" ja jatkuu 2,5" perälle asti. Sitten kun kansi ja venakoppa tulee, niin pääsee kasaamaan. Pakosarja on vielä pinnoitettavana, joten sitä saa odotella. Öljynpaluun voisi tehdä öljypohjaan, mutta hölmönä otin moottoripukin lainaan vasta kannen irroituksen jälkeen (ei oikeen voi nostaa pukille). Täytynee odottaa kantta ja sen asennusta siis ennen öljypaluun tekoa. Ostin läpipultattavan mallin, ehdotuksia otetaan vastaan jostain öljynkestävästä kierrelukitteesta.

To do lista tällä hetkellä:

- Korisarjan kiinnitykset kuntoon

- Ovien listojen kiinnitykset

- Ulkonäkö

- Takaikkunaa ympäröivien ruosteiden kiinniotto (ammattilaisella)

- (Ylimaalaus)

- Puskurien halkeamat kuntoon

- Antenni pois

- Konehuoneen maalaus/siistiminen

- Turbon lokasuojan teko ja maalaus

- Käyntihäiriön korjaus (alipainevuoto?)

- Ahtaminen

- Välijäähdyttimen sovittaminen ja kiinnitys

- Ahtoputket

- Turbo öljymeno suodatinjalasta M10 banjo

- Turbo öljynpaluun teko öljypohjaan

- Turbon veden meno ja paluu

- Downpipen teko ja teippaus

- Hukkaportin asennus ja reititys DP

- "Väliseinä" ilmansuodatinkotelon ja moottorin väliin

- Imusarjan pituuden ohjaus pois (ahtoputkea varten)

- Huohotuksen uudelleenreititys

- Ahtopaineen ohjauksen asennus (venttiili ja johdotus)

- Penkitys

- Muutoskatsastus

Daily driver: Projekti, koska luotettavat autot ovat tylsiä Luotettava, eli tylsä CLK 270

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Re: W201 2.0 8V -> 2.8 24V MS2 V3.0

Hyvää settiä taas!

Nokassa vähän "rokkoa", melkein pinnottaisin tuon keraamisella liukupinnoitteella että ei nostaja taas lähde kulumaan.

Saman kaltaista ongelmaa oli klonkswageni riiselissä ja se korjaantui techlinen cermalube pinnoitteella.

Tulee kyllä makea laite tuosta kunhan valmiiksi saat!

Nokassa vähän "rokkoa", melkein pinnottaisin tuon keraamisella liukupinnoitteella että ei nostaja taas lähde kulumaan.

Saman kaltaista ongelmaa oli klonkswageni riiselissä ja se korjaantui techlinen cermalube pinnoitteella.

Tulee kyllä makea laite tuosta kunhan valmiiksi saat!

Re: W201 2.0 8V -> 2.8 24V MS2 V3.0

KiitosMJPfin kirjoitti: ↑To 28.12.2023 21:33 Hyvää settiä taas!

Nokassa vähän "rokkoa", melkein pinnottaisin tuon keraamisella liukupinnoitteella että ei nostaja taas lähde kulumaan.

Saman kaltaista ongelmaa oli klonkswageni riiselissä ja se korjaantui techlinen cermalube pinnoitteella.

Tulee kyllä makea laite tuosta kunhan valmiiksi saat!

Projekti etenee hiljalleen. MAC-venttiili saaapui, joten tein sille kannakkeen.

Tuo tulee akkukotelon puolelle, niin PETG kestänee. Jos ei, niin keksin jotain muuta.

Kansi ja öljynsuodattimen jalka tulivat koneistajalta (HS-koneistus). Kantta kasattaessa kävi muutama pikku virhe, kuten esimerkiksi moottori oli 6. sylinterin mukaan yläkuolonkohdassa 1. sylinterin sijasta. No, kuvaa ja videota siitäkin saatiin.

Pakosarja tuli pinnoituksesta ja siitä tuli oikein sievä. Pinnoitus on C-7300 BLACK VELVET

Tein myös öljynpaluun turbolle

CNC-työstökeskus, eli Deuzerin akkukone vuodelta 2017 sai tämänkin työn hoitaa

Venttiilikoppa ja etulokari tulivat maalarilta (lokasuojasta ei ole vielä kuvaa) ja niistä tuli hyvät. En ohjeistanut venttiilikopan puhalluksesta sitä, että hiekalla ei saisi puhaltaa ja täynnä öljyhiekkamoskaahan se oli

Venttiilikoppa, öljypohja ja pakosarja kiinni moottori näyttää nyt tältä

Odottelen tilausta ruotsalaisilta (do88), jonka saavuttua pääsen mitoittamaan turbon vesiletkuja. Veden paluu menee öljynsuodatinjalan viereen ja lähdön haaroitan lämppäriin menevästä putkesta. Sen jälkeen imusarja löytänee kiinni ja alan miettimään sokeaa tuon imusarjan pituuden ohjauksen paikalle. Tämän jälkeen en näe syytä olla laittamatta moottoria paikalleen. Turboa pitää hieman käännellä, että saan öljynpaluun vaakasuoraan ja se ei onnistu tarvittavalla tarkkuudella ennen kuin moottori on paikallaan. Siitä sitten ahtoputkien, välijäähdyttimen, downpipen ja hukkaportin ihmettelyyn.

To do lista tällä hetkellä:

- Korisarjan kiinnitykset kuntoon

- Ovien listojen kiinnitykset

- Ulkonäkö

- Takaikkunaa ympäröivien ruosteiden kiinniotto (ammattilaisella)

- (Ylimaalaus)

- Puskurien halkeamat kuntoon

- Antenni pois

- Konehuoneen maalaus/siistiminen

- Turbon lokasuojan teko ja maalaus

- Käyntihäiriön korjaus (alipainevuoto?)

- Ahtaminen

- Välijäähdyttimen sovittaminen ja kiinnitys

- Ahtoputket

- Turbo öljymeno suodatinjalasta M10 banjo

- Turbo öljynpaluun teko öljypohjaan

- Turbon veden meno ja paluu

- Downpipen teko ja teippaus

- Hukkaportin asennus ja reititys DP

- "Väliseinä" ilmansuodatinkotelon ja moottorin väliin

- Imusarjan pituuden ohjaus pois (ahtoputkea varten)

- Huohotuksen uudelleenreititys

- Ahtopaineen ohjauksen asennus (venttiili ja johdotus)

- Penkitys

- Muutoskatsastus

Daily driver: Projekti, koska luotettavat autot ovat tylsiä Luotettava, eli tylsä CLK 270

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Re: W201 2.0 8V -> 2.8 24V MS2 V3.0

Hyvän näköistä setti!

Kiva nähdä mitä tulee penkissä työntämään.

Kiva nähdä mitä tulee penkissä työntämään.

Re: W201 2.0 8V -> 2.8 24V MS2 V3.0

Kiitokset

Sain kiinnitettyä imusarjan, polttoainekiskon ja muuta tilpehööriä moottoriin. Kytkin ja vaihdelaatikko kiinni ja pannu sisälle...

Paisuntasäiliö ja ilmansuodatinkotelo eivät valitettavasti mahtuneet tuolla olemaan, joten takaisin piirrustuspöydälle niiden kera. Sain kuitenkin turbon käännettyä ja sen elinnesteletkuja kiinni. Kääntämisen jälkeen öljynpaluu törmäsi yhteen kompressorikotelon kiinnityspulttiin ja siihen piti laittaa uppokantanen tilalle. Paluu on nyt kuitenkin valmis:

Vesiletku on vähän lämpimässä paikassa, saa nähdä pitääkö vielä keksiä uudelleen tuo lähtö. Turbolle tulee huppu, joka pelastaa vähän.

Ilmansuodattimen ja paisuntasäiliön kanssa ratkaisu ei ole elegantein, mutta toiminee. Mielessä kävi tuon suodattimen kotelointi jollain alumiini/RST-pellillä, mutta täytynee ensin katsoa mitä imulämmöt sanovat.

Muutenhan tuo on hyvällä mallilla. Sähköt moottorin päästä, vaihdelaatikko, kardaani, vaihteensiirtäjä ym. ovat kiinni ja polttoainejärjestelmä on kiinni. Tehtävääkin on: ahtoputket, välijäähdytin, DP, hukkaportti, lämppärin vesiputki ja sähköjen viimeistely/uudet kytkennät. Sitten toki lokasuojaa, puskuria ja listoja kiinni.

To do lista tällä hetkellä:

- Korisarjan kiinnitykset kuntoon

- Ovien listojen kiinnitykset

- Ulkonäkö

- Takaikkunaa ympäröivien ruosteiden kiinniotto (ammattilaisella)

- (Ylimaalaus)

- Puskurien halkeamat kuntoon

- Antenni pois

- Konehuoneen maalaus/siistiminen

- Turbon lokasuojan teko ja maalaus

- Käyntihäiriön korjaus (alipainevuoto?)

- Ahtaminen

- Välijäähdyttimen sovittaminen ja kiinnitys

- Ahtoputket

- Turbon veden meno ja paluu

- Downpipen teko ja teippaus

- Hukkaportin asennus ja reititys DP

- "Väliseinä" ilmansuodatinkotelon ja moottorin väliin

- Imusarjan pituuden ohjaus pois (ahtoputkea varten)

- Huohotuksen uudelleenreititys

- Ahtopaineen ohjauksen asennus (venttiili ja johdotus)

- Penkitys

- Muutoskatsastus

Daily driver: Projekti, koska luotettavat autot ovat tylsiä Luotettava, eli tylsä CLK 270

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Re: W201 2.0 8V -> 2.8 24V MS2 V3.0

Noot vesilähdöt kannattaa viedä sellaiset 150-200mm putkella pois turbon rungon vierestä ennen kuin vetää letkulla.

Se on aika ikävää kun vesiletku päättää että liian kuuma ja lähtee irti.

Kauheasti savuhöyry juttua pellin alta ja paniikki että nytkö se räjähti. Ja hirveä siivoaminen

Se on aika ikävää kun vesiletku päättää että liian kuuma ja lähtee irti.

Kauheasti savuhöyry juttua pellin alta ja paniikki että nytkö se räjähti. Ja hirveä siivoaminen

Re: W201 2.0 8V -> 2.8 24V MS2 V3.0

Tarvikemotista katselin jotain vaihtoehtoja, mutta heikosti oli saatavuutta. 16mm banjo ja 12-13mm letkulähtö tarvitsisi olla. Löytyisköhän jostain hydrauliikkaliikkeestä? Mielessä kävi jo, että itse taivuttelisi ja hitsaisi pätkät väliin.MJPfin kirjoitti: ↑La 16.03.2024 12:36 Noot vesilähdöt kannattaa viedä sellaiset 150-200mm putkella pois turbon rungon vierestä ennen kuin vetää letkulla.

Se on aika ikävää kun vesiletku päättää että liian kuuma ja lähtee irti.

Kauheasti savuhöyry juttua pellin alta ja paniikki että nytkö se räjähti. Ja hirveä siivoaminen

Daily driver: Projekti, koska luotettavat autot ovat tylsiä Luotettava, eli tylsä CLK 270

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Re: W201 2.0 8V -> 2.8 24V MS2 V3.0

Hytikka puljuun vaan hakemaan tai sit hitsailee tigillä ite jatkoja tai kovajuottaa yms.

Re: W201 2.0 8V -> 2.8 24V MS2 V3.0

noihin saa myös palosuojaletkua, ainakin mustaa ja punaista. Laittaa vielä oetiker letkunkiristimen niin mahtuu vetää ns. ylitse asti koko suojaletkun.

esim. : https://www.usparts.fi/performance/letk ... /palosuoja

esim. : https://www.usparts.fi/performance/letk ... /palosuoja

Re: W201 2.0 8V -> 2.8 24V MS2 V3.0

Tuo palosuoja kävi mielessä myös, on vaan hintava vaihtoehtoepk kirjoitti: ↑La 16.03.2024 13:09 noihin saa myös palosuojaletkua, ainakin mustaa ja punaista. Laittaa vielä oetiker letkunkiristimen niin mahtuu vetää ns. ylitse asti koko suojaletkun.

esim. : https://www.usparts.fi/performance/letk ... /palosuoja

Eli letkut tulevat huomattavasti viileämpään paikkaan.

Daily driver: Projekti, koska luotettavat autot ovat tylsiä Luotettava, eli tylsä CLK 270

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Re: W201 2.0 8V -> 2.8 24V MS2 V3.0

Todella asiallisen näköisesti tulee!

Kiva seurata kun askarrellaan siististi. Niitä rälläkkä ja rautasaha rautalokinpaska, purkka virityksiä näkee ihan tarpeeksi.

Kiva seurata kun askarrellaan siististi. Niitä rälläkkä ja rautasaha rautalokinpaska, purkka virityksiä näkee ihan tarpeeksi.

Re: W201 2.0 8V -> 2.8 24V MS2 V3.0

Hieno projekti ja hienosti toteutettu.

Siitä nopeusmittarin toiminnasta pitää muistuttaa että virallisten pykälien mukaan nopeustieto pitää tulla autolta, ei taivaalta. Joku inssi saattaa jossain vaiheessa puuttua asiaan.

Siitä nopeusmittarin toiminnasta pitää muistuttaa että virallisten pykälien mukaan nopeustieto pitää tulla autolta, ei taivaalta. Joku inssi saattaa jossain vaiheessa puuttua asiaan.

Re: W201 2.0 8V -> 2.8 24V MS2 V3.0

Täytyy myöntää, että on niitä joskus itsekin tullut tehtyä... 10v omistajuuden aikana on vaan päässyt käymään niin, että itse ne on saanut korjata

Kiitokset. Kieltämättä tuo on käynyt mielessä. Perästä saisi ABS-anturilta tiedon ja tuon jo kiinni olevan Arduinon kanssa saisi tiedon mittarille asti melko pienellä vaivalla. Sattuu olemaan hyllyssä pussillinen toimintasavuttomia MAX9926 muuntimiakin. Lutikoitakin löytyisi niihin.

Toi GPS-signaali, vaikka ihan laadukkailla osilla omassa tapauksessa tehty, ei ole mitä luotettavin. Ihan syystä pykälät sanoo noin. Laitan vähän mietintämyssyä päähän.

Daily driver: Projekti, koska luotettavat autot ovat tylsiä Luotettava, eli tylsä CLK 270

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Re: W201 2.0 8V -> 2.8 24V MS2 V3.0

Kai sitä kehtaa jonkinlaisen päivityksenkin tehdä, kun on edennytkin

Tein välijäähdyttimen kannakoinnin niin, että käristin jäähdyttimen kannakkeeseen lisää rautaa. Välijäähy on kiinnitetty periaatteella:

Välijäähdytin

--Kumi--

Kannake

--Kumi--

Pultti

Muutama kuva:

Kun välijäähdytin oli kannatettu, siirryin ahtoputkien sovitukseen:

Blow-offin viereen piti hitsata imuilman lämpötila-anturille paikka vielä ennen viimeisiä kiristyksiä

Ja näin ahtoputketkin alkoi löytämään paikkaansa:

Kannakkeena ihan Bilteman LVI-osastolta haettuja kannakkeita... Ajanee asiansa.

Kuvasta ei näy, mutta BOV on tuettu imusarjan kohdalta myös.

Hukkaportin ohjausta varten piti keksiä venttiilille kannake. Olin sellaisen jo tulostanut, mutta päädyin kuitenkin peltiseen

5mm lähdöt vaihtuivat 6mm kokoon

Hukkaportin jousi piti tarkistaa ja hyvä, että tarkistin. Liekö ollut 3bar jousiyhdistelmä sisässä

Kompuralla mitattuna tällä jousella avautuminen on jossain 0,8-1,0bar välillä. Hukkaportti nippuun:

Downpipen rakentelua varten yksi hyvä kaveri ilmoittautui vapaaehtoiseksi. Ahdas välihän tuo on...

Osat esille ja ihmettelemään.

Useita tunteja myöhemmin:

Ja lopulta:

Tuskaa tuotti tuo hukkaportin tuominen suoraan putkeen. Koria ei muokattu tätä varten vielä ollenkaan, mutta jokin lovi täytyy tehdä myöhemmin. Tuosta tuli todella hyvä. Täytyy vielä tehdä toinen osuus, jossa on yksi jousto ja lambdan paikka.

Jarruja varten tilasin R129-partsilta olka-akselit (1293300220 ja 1293300320) ja jarrusatulat (1294200083 ja 1294200183).

Nuo oli todella hyvin pakattu, vaikkei sitä päällepäin näekään:

Olka-akseleissa oli kaikki pultit ja jarrukilpikin mukana

Eivät nuo uudet ole, mutta ihan kohtalaisessa kunnossa

Puhalsin soodalla suurimmat pois ja tarkoitus on maalata hopeiseksi, jotta ovat samanlaiset kuin takana. Oikealla puhaltamaton.

Tilasin myös uudet tiivisteet ja pölysuojat, mutta ne eivät ole vielä saapuneet. Laitan nuo jarrut kiinni kunhan joutaa, mutta ennen katsastusta kuitenkin To-do listalta lähtee muutamakin asia tällä kertaa.

To-do listalta lähtee muutamakin asia tällä kertaa.

To do lista tällä hetkellä:

Tein välijäähdyttimen kannakoinnin niin, että käristin jäähdyttimen kannakkeeseen lisää rautaa. Välijäähy on kiinnitetty periaatteella:

Välijäähdytin

--Kumi--

Kannake

--Kumi--

Pultti

Muutama kuva:

Kun välijäähdytin oli kannatettu, siirryin ahtoputkien sovitukseen:

Blow-offin viereen piti hitsata imuilman lämpötila-anturille paikka vielä ennen viimeisiä kiristyksiä

Ja näin ahtoputketkin alkoi löytämään paikkaansa:

Kannakkeena ihan Bilteman LVI-osastolta haettuja kannakkeita... Ajanee asiansa.

Kuvasta ei näy, mutta BOV on tuettu imusarjan kohdalta myös.

Hukkaportin ohjausta varten piti keksiä venttiilille kannake. Olin sellaisen jo tulostanut, mutta päädyin kuitenkin peltiseen

5mm lähdöt vaihtuivat 6mm kokoon

Hukkaportin jousi piti tarkistaa ja hyvä, että tarkistin. Liekö ollut 3bar jousiyhdistelmä sisässä

Kompuralla mitattuna tällä jousella avautuminen on jossain 0,8-1,0bar välillä. Hukkaportti nippuun:

Downpipen rakentelua varten yksi hyvä kaveri ilmoittautui vapaaehtoiseksi. Ahdas välihän tuo on...

Osat esille ja ihmettelemään.

Useita tunteja myöhemmin:

Ja lopulta:

Tuskaa tuotti tuo hukkaportin tuominen suoraan putkeen. Koria ei muokattu tätä varten vielä ollenkaan, mutta jokin lovi täytyy tehdä myöhemmin. Tuosta tuli todella hyvä. Täytyy vielä tehdä toinen osuus, jossa on yksi jousto ja lambdan paikka.

Jarruja varten tilasin R129-partsilta olka-akselit (1293300220 ja 1293300320) ja jarrusatulat (1294200083 ja 1294200183).

Nuo oli todella hyvin pakattu, vaikkei sitä päällepäin näekään:

Olka-akseleissa oli kaikki pultit ja jarrukilpikin mukana

Eivät nuo uudet ole, mutta ihan kohtalaisessa kunnossa

Puhalsin soodalla suurimmat pois ja tarkoitus on maalata hopeiseksi, jotta ovat samanlaiset kuin takana. Oikealla puhaltamaton.

Tilasin myös uudet tiivisteet ja pölysuojat, mutta ne eivät ole vielä saapuneet. Laitan nuo jarrut kiinni kunhan joutaa, mutta ennen katsastusta kuitenkin

To do lista tällä hetkellä:

- Korisarjan kiinnitykset kuntoon

- Ovien listojen kiinnitykset

- Ulkonäkö

- Takaikkunaa ympäröivien ruosteiden kiinniotto (ammattilaisella)

- (Ylimaalaus)

- Puskurien halkeamat kuntoon

- Antenni pois

- Konehuoneen maalaus/siistiminen

- Etupuskurin muokkaus välijäähdytintä varten

- Käyntihäiriön korjaus (alipainevuoto?)

- Ahtaminen

- Välijäähdyttimen sovittaminen ja kiinnitys

- Ahtoputket

- Turbon veden meno ja paluu

- Downpipen teko ja teippaus (1/2 valmis...)

- Hukkaportin asennus ja reititys DP

- "Väliseinä" ilmansuodatinkotelon ja moottorin väliin Ei tehdä

- Huohotuksen uudelleenreititys

- Ahtopaineen ohjauksen asennus (venttiili ja johdotus)

- Muuta

- Lämmitinlaitteen veden meno

- Olka-akselit ja jarrusatulat kiinni

- Tuulettimen releen kytkentä Arduino

- Penkitys

- Muutoskatsastus

Daily driver: Projekti, koska luotettavat autot ovat tylsiä Luotettava, eli tylsä CLK 270

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Re: W201 2.0 8V -> 2.8 24V MS2 V3.0

Päivitystä!

Ensimmäinen koeajo suoritettu ahdoilla. Kartta oli tyystin liian rikkaalla ja boost cut päällä heti kun pääsi ahdoille, mutta kyllä sillä tunnelmaan pääsi DP tuli valmiiksi ja teipattua. Konehuone alkaa näyttämään jo valmiilta

DP tuli valmiiksi ja teipattua. Konehuone alkaa näyttämään jo valmiilta

Lämmitinlaitteen putken väänsin happamasta. Puuilon 16mm putkentaivutin ei antanut periksi 2,0mm seinämävahvuudenkaan kanssa

Ahtopaineen säätöventtiili löysi paikkansa myös

Huohotus toimii niin, että keruusäiliölle tulee alipaine ilmansuodattimen vierestä ja säiliö imee kampikammion huurut. Yläpäässä on 25mm kulma, T-pala ja letkua ja päässä suodatin. Huohotus on vielä vähän kesken, mutta tässä yläpäästä kuva

Jarrusatulat sai hopeisen maalin niskaan

Satuloiden huoltoon ostin uudet kumit. Älkää ostako noita, missä pölynsuojakumien raudat ovat erikseen, ei pysy kiinni ja aivan mahdoton asentaa. Ostin lopulta sellaiset, missä tuo rautalanka on kumiin sisäänrakennettu ja niillä homma luonasi hyvin.

Etulokasuojakin löysi paikkansa ja siitähän tuli vallan hyvännäköinen. Vähän pölyjä tuossa on pinnassa, mutta tästä lähin käytän muutenkin eri pintakäsittelijää venttiilikoppaepisodinkin takia.

Lähdin myös rakentamaan välijäähdyttimen vesiruiskua. Bilteman 2,5l pesunestesäiliö, 2 viuhkamallista suutinta ja koodia Arduinoon

Ensimmäinen versio koodista tässä

Eli ohjataan suihku päälle, kun kaasunasento on yli 80%, paine yli 150kPa (absoluuttista) ja imuilma on yli 20°C ulkolämpötilaa lämpimämpi. Toisessa skenaariossa suihku kytketään kolmeksi sekunniksi, jos imuilma on yli 30°C ulkolämpötilaa lämpimämpi, vauhtia on yli 30km/h ja spray ei ole 15 sekunnin aikana ollut päällä (toisen skenaarion kautta).

Välijäähdyttimen kastelemisesta on joitain tutkimuksiakin, tässä yksi: https://www.researchgate.net/publicatio ... y's_Nozzle

Samasta lähteestä välijäähdyttimen hyötysuhteen vertailua eri suuttimilla. Olennaista tässä se, että ilman suihkutusta hyötysuhde on huomattavasti matalampi. Hyötysuhde on tässä tapauksessa se, kuinka ison osan lämmöstä välijäähdytin poistaa ahdetusta (lämmitetystä) ilmasta. Jos ulkolämpötila on 20°C, välijäähdyttimeen menevä ilma 60°C ja sieltä ulos tuleva ilma 40°C, niin hyötysuhde on (40-20)/(60-20) = 50 %

Josko tuon suihkun, turbohupun, pakosarjan pinnoituksen ja downpipen lämpökääreiden yhdistelmällä pysyisi lämmöt kurissa tässä autossa. Keulalla on kaksi sähkötuuletinta vielä Arduinon ohjaamana. Katsotaan josko penkissä saisi testattua miten todellisuudessa vaikuttaa.

Jatkosta sen verran, että penkkiaika on varattuna 9.5. ja katsastuskonttorin kanssa on keskustelu avattu muutoksien saamisesta otteeseen. Aivan optimitilanteessa tämä on 10.5. muutoksilla katsatettu, mutta katsotaan miten käy

To do lista tällä hetkellä:

Ensimmäinen koeajo suoritettu ahdoilla. Kartta oli tyystin liian rikkaalla ja boost cut päällä heti kun pääsi ahdoille, mutta kyllä sillä tunnelmaan pääsi

Lämmitinlaitteen putken väänsin happamasta. Puuilon 16mm putkentaivutin ei antanut periksi 2,0mm seinämävahvuudenkaan kanssa

Ahtopaineen säätöventtiili löysi paikkansa myös

Huohotus toimii niin, että keruusäiliölle tulee alipaine ilmansuodattimen vierestä ja säiliö imee kampikammion huurut. Yläpäässä on 25mm kulma, T-pala ja letkua ja päässä suodatin. Huohotus on vielä vähän kesken, mutta tässä yläpäästä kuva

Jarrusatulat sai hopeisen maalin niskaan

Satuloiden huoltoon ostin uudet kumit. Älkää ostako noita, missä pölynsuojakumien raudat ovat erikseen, ei pysy kiinni ja aivan mahdoton asentaa. Ostin lopulta sellaiset, missä tuo rautalanka on kumiin sisäänrakennettu ja niillä homma luonasi hyvin.

Etulokasuojakin löysi paikkansa ja siitähän tuli vallan hyvännäköinen. Vähän pölyjä tuossa on pinnassa, mutta tästä lähin käytän muutenkin eri pintakäsittelijää venttiilikoppaepisodinkin takia.

Lähdin myös rakentamaan välijäähdyttimen vesiruiskua. Bilteman 2,5l pesunestesäiliö, 2 viuhkamallista suutinta ja koodia Arduinoon

Ensimmäinen versio koodista tässä

Koodi: Valitse kaikki

void ICSControl()

{

unsigned long ICSCcurrentMillis = millis(); // Record current time

if (ICSCcurrentMillis - ICSClastExecutedMillis >= ICSC_EXE_INTERVAL) //If elapsed time from last execution is more than the specified interval

{

ICSClastExecutedMillis = ICSCcurrentMillis;

//If throttle position is above 80 %, MAP above 150 kPa, IAT temperature more than 20°C above ambient

if (bCastMsg.tps >= 80 && bCastMsg.map >= 150 && (((bCastMsg.clt-32)*5/9)-(ATaverage/10)) >= 20 && ICSCstatus == 0)

{

digitalWrite(ICSCpin, HIGH);

Serial.println("IC Spray ON");

ICSCstatus = 1;

}

//Or if IAT temperature more than 30°C above ambient and speed more than 30 km/h and spray was last on more than 15s ago

else if ((((bCastMsg.clt-32)*5/9)-(ATaverage/10)) >= 30 && bCastMsg.gps_speed*3.6 > 30 && ICSCstatus == 0 && ICSCcurrentMillis - ICSCOnMillis >= 15000)

{

digitalWrite(ICSCpin, HIGH);

Serial.println("IC Spray ON");

ICSCstatus = 1;

ICSCOnMillis = ICSCcurrentMillis;

}

else

{

digitalWrite(ICSCpin, LOW);

Serial.println("IC Spray OFF");

ICSCstatus = 0;

}

if(ICSCcurrentMillis - ICSCOnMillis >= 3000)

{

digitalWrite(ICSCpin, LOW);

Serial.println("IC Spray OFF");

ICSCstatus = 0;

}

}

}Välijäähdyttimen kastelemisesta on joitain tutkimuksiakin, tässä yksi: https://www.researchgate.net/publicatio ... y's_Nozzle

Samasta lähteestä välijäähdyttimen hyötysuhteen vertailua eri suuttimilla. Olennaista tässä se, että ilman suihkutusta hyötysuhde on huomattavasti matalampi. Hyötysuhde on tässä tapauksessa se, kuinka ison osan lämmöstä välijäähdytin poistaa ahdetusta (lämmitetystä) ilmasta. Jos ulkolämpötila on 20°C, välijäähdyttimeen menevä ilma 60°C ja sieltä ulos tuleva ilma 40°C, niin hyötysuhde on (40-20)/(60-20) = 50 %

Josko tuon suihkun, turbohupun, pakosarjan pinnoituksen ja downpipen lämpökääreiden yhdistelmällä pysyisi lämmöt kurissa tässä autossa. Keulalla on kaksi sähkötuuletinta vielä Arduinon ohjaamana. Katsotaan josko penkissä saisi testattua miten todellisuudessa vaikuttaa.

Jatkosta sen verran, että penkkiaika on varattuna 9.5. ja katsastuskonttorin kanssa on keskustelu avattu muutoksien saamisesta otteeseen. Aivan optimitilanteessa tämä on 10.5. muutoksilla katsatettu, mutta katsotaan miten käy

To do lista tällä hetkellä:

- Korisarjan kiinnitykset kuntoon

- Ovien listojen kiinnitykset

- Ulkonäkö

- Takaikkunaa ympäröivien ruosteiden kiinniotto (ammattilaisella)

- (Ylimaalaus)

- Puskurien halkeamat kuntoon

- Antenni pois

- Konehuoneen maalaus/siistiminen

- Etupuskurin muokkaus välijäähdytintä varten

- Käyntihäiriön korjaus (alipainevuoto?)

- Ahtaminen

- Downpipen teko ja teippaus

- Huohotuksen uudelleenreititys

- Ahtopaineen ohjauksen asennus (venttiili ja johdotus)

- Muuta

- Lämmitinlaitteen veden meno

- Olka-akselit ja jarrusatulat kiinni

- Tuulettimen releen kytkentä Arduino

- Penkitys

- Muutoskatsastus

Viimeksi muokannut Mighty190, Pe 31.05.2024 15:16. Yhteensä muokattu 1 kertaa.

Daily driver: Projekti, koska luotettavat autot ovat tylsiä Luotettava, eli tylsä CLK 270

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Re: W201 M104 MS2 V3.0 Turbo

Jatketaan.

Huohotusta varten tein 10mm lähdön ilmansuodattimen ja turbon väliin.

Laitoin myös R129 SL500 etujarrut ja etuolka-akselit paikalleen. Jarrut kasvoivat taas hieman.

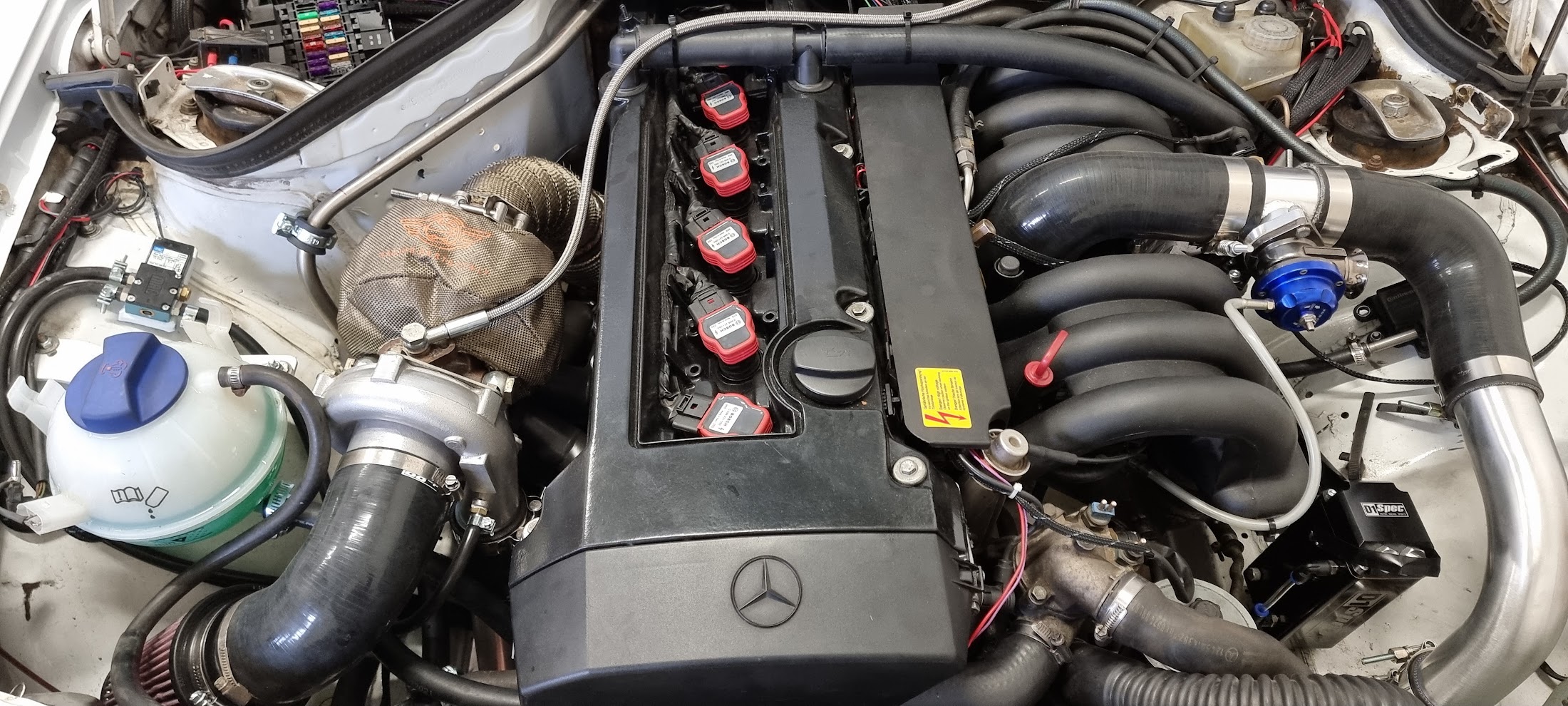

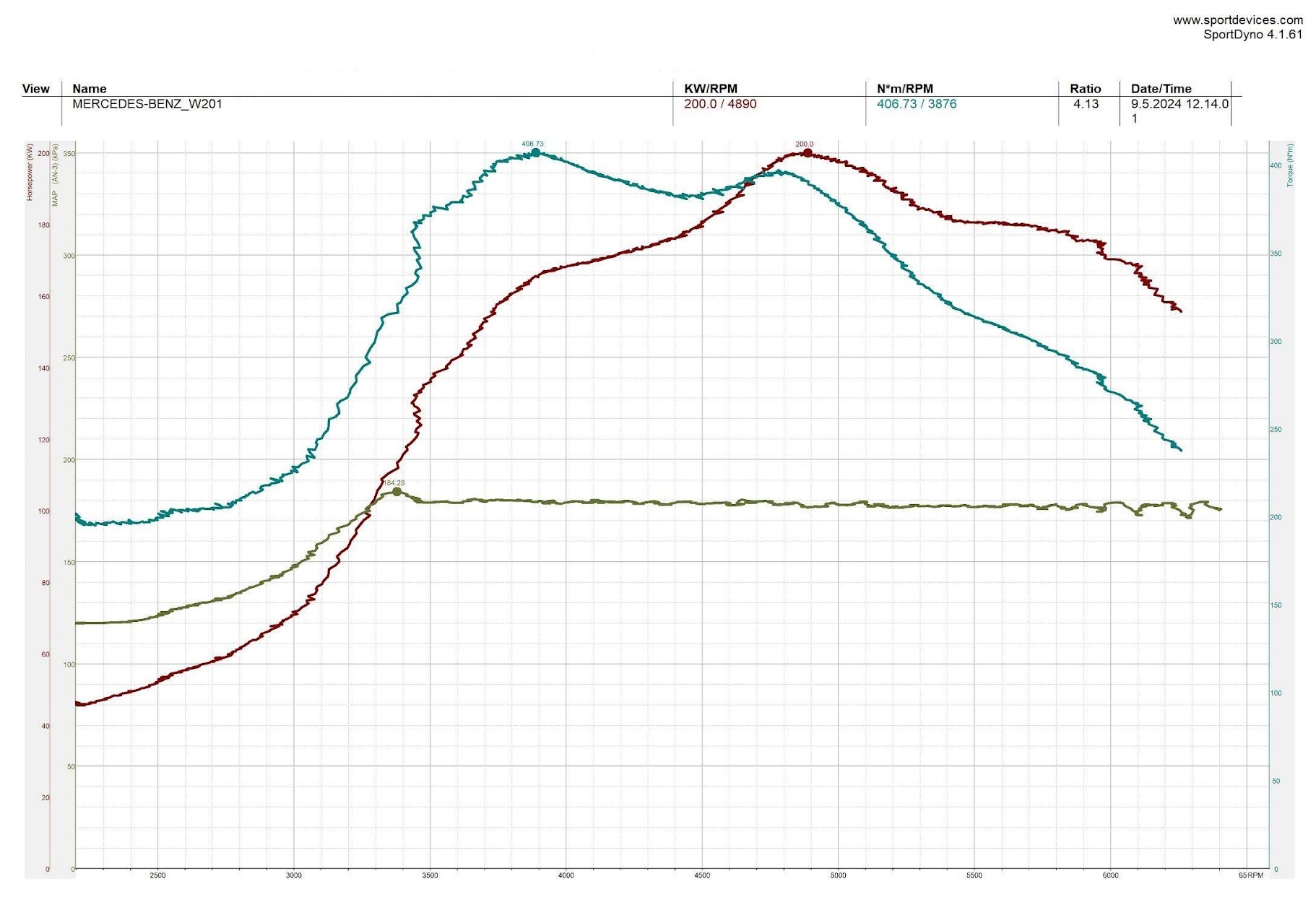

09.05.2024 oli tehonmittaus ja 10.05.2024 tuli leima lappuun kaikilla muutoksilla

200kW/407Nm antoi navalta, joten tehot jäivät vähäisiksi. Toisaalta ei lyö tyhjää noilla tehoilla, eli kaiken saa tiehen Nokka-akselin ohjaus ei jostain syystä megan ohjaamana toiminut, mutta se onkin tätä nykyä jo Arduinon takana.

Nokka-akselin ohjaus ei jostain syystä megan ohjaamana toiminut, mutta se onkin tätä nykyä jo Arduinon takana.

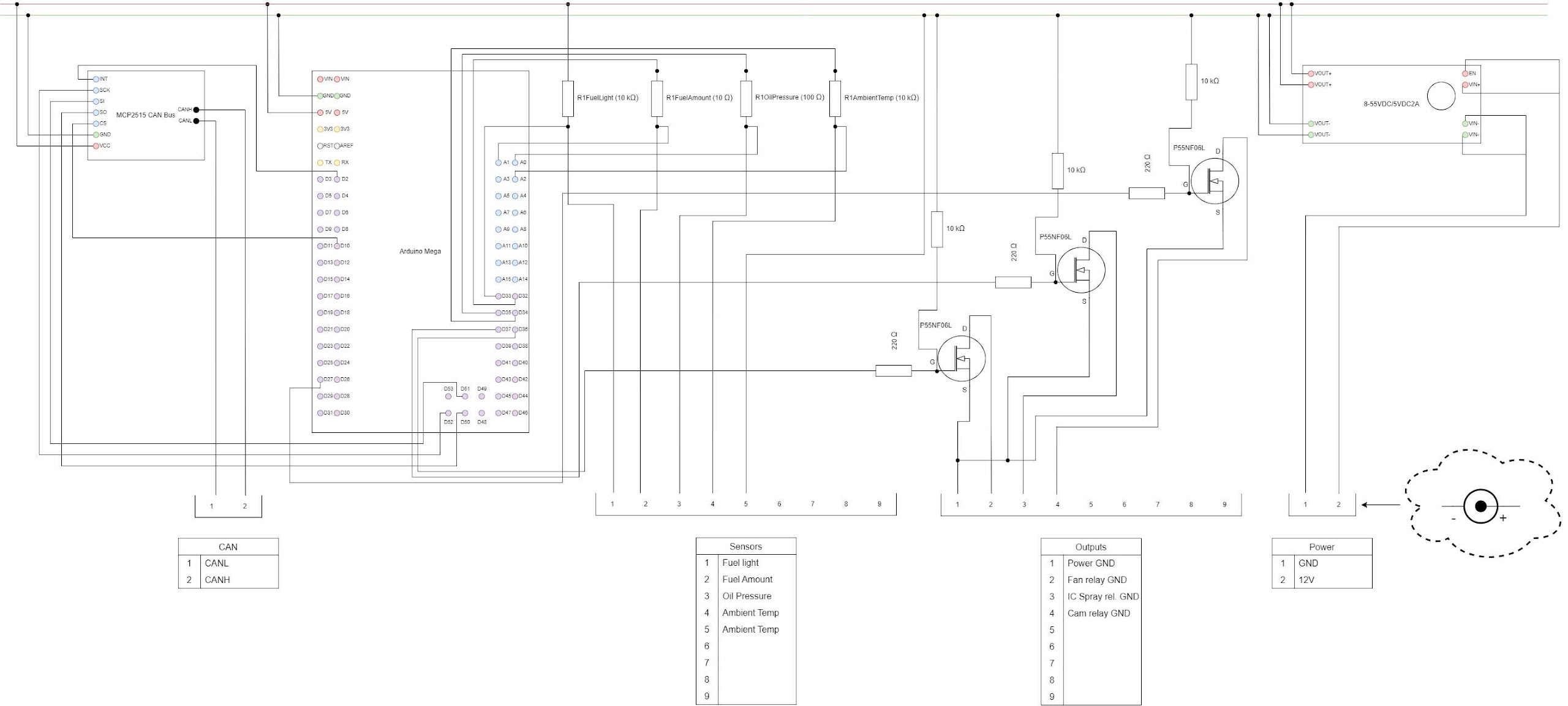

Arduinon päivitetty koodi ja piirikaavio

Näissä suurimpina muutoksina 3. ohjattava ulostulo ja se, että ulostulojen tilatieto lähetetään Megalle. Tilatieto ajetaan Arduinossa outputStates muuttujaan, joka menee adc4 muuttujana sitten CAN-väylään.

Tunerstudion puolella gpioadc4 muuttuja on maincontroller.inin mukaan taulukossa 112. Tästä saadaan yksittäiset 3 bittiä ulos eri ulostuloille, kun laittaa custom.ini -tiedostoon [OutputChannels] alle tämän:

Jossa siis esimerkiksi [0:0] viittaa siihen, että haetaan vain bitistä 0 bittiin 0, eli CoolantFan arvo on 0 tai 1. custom.ini puolella voi laittaa myös datalogiin lisää kenttiä [Datalog] alle:

Näin logissa näkyy myös se, että milloin ohjaukset ovat olleet päällä. Toki, ohjaus voi olla päällä ja tuuletin ei pyöri vaikkapa rikkinäisen releen takia.

Tuuletinta varten laitoin indikaattorin ja siihen kuvan, että näkee milloin tuuletin on päällä. Kuvassa testimoodi, eli kun kierrokset ovat alle 500 ja kaasunasento yli 80%, niin ulostuloja loopataan päälle.

To do lista tällä hetkellä:

Huohotusta varten tein 10mm lähdön ilmansuodattimen ja turbon väliin.

Laitoin myös R129 SL500 etujarrut ja etuolka-akselit paikalleen. Jarrut kasvoivat taas hieman.

09.05.2024 oli tehonmittaus ja 10.05.2024 tuli leima lappuun kaikilla muutoksilla

200kW/407Nm antoi navalta, joten tehot jäivät vähäisiksi. Toisaalta ei lyö tyhjää noilla tehoilla, eli kaiken saa tiehen

Arduinon päivitetty koodi ja piirikaavio

Koodi: Valitse kaikki

#include <SPI.h>

#include <mcp2515.h> //https://github.com/autowp/arduino-mcp2515

#include <MegaCAN.h> //https://github.com/mantonakakis1/MegaCAN

//Sensor libraries

//Ambient temperature

#include <MBAmbientTemp.h>

AmbientTemp AT;

#define AT_EXE_INTERVAL 200 // How often Ambient Temperature is measured (ms)

unsigned long ATlastExecutedMillis = 0; // Variable to save the last executed time

//Oil Pressure

#include <MBOilPressure.h>

OilPressure OP;

#define OP_EXE_INTERVAL 50 // How often Oil Pressure is measured (ms)

unsigned long OPlastExecutedMillis = 0; // Variable to save the last executed time

//Fuel Amount

#include <MBFuelAmount.h>

FuelAmount FA;

#define FA_EXE_INTERVAL 100 // How often Fuel Amount is measured (ms)

#define FW_EXE_INTERVAL 100 // How often Fuel Warning is measured (ms)

unsigned long FAlastExecutedMillis = 0; // Variable to save the last executed time

unsigned long FWlastExecutedMillis = 0; // Variable to save the last executed time

//Outputs

//Fan Control

#define FC_EXE_INTERVAL 1000 // How often Fan Control algo runs (ms)

unsigned long FClastExecutedMillis = 0; // Variable to save the last executed time

const int FCpin = 36; // Physical pin

bool FCstatus;

//IC Spray Control

#define ICSC_EXE_INTERVAL 300 // How often IC Spray Control algo runs (ms)

unsigned long ICSClastExecutedMillis = 0; // Variable to save the last executed time

unsigned long ICSCOnMillis = 0; // Variable to save the last executed time

const int ICSCpin = 37; // Physical pin

bool ICSCstatus;

//Camshaft Control

#define CS_EXE_INTERVAL 200 // How often Fan Control algo runs (ms)

unsigned long CSlastExecutedMillis = 0; // Variable to save the last executed time

const int CSpin = 19; // Physical pin

bool CSstatus;

//Test variable for outputs

int output = 1;

//MegaCAN

#define CELSIUS // MegaCAN uses Fahrenheit, which is no good. This transforms broadcasted temperatures to Celsius

//MegaCAN

const uint32_t baseID = 1512; // Must set to match Megasquirt Settings!

const uint32_t finalID = baseID + 17; // Must set to match Megasquirt Settings configured in TunerStudio! The last group of data broadcasted.

//MCP2515 related

struct can_frame receivedFrame;

MCP2515 mcp2515(10); //CS at D10

MegaCAN MegaCAN; // For processed Megasquirt CAN protocol messages

MegaCAN_message_t recMsgMSC; // Stores received message from Megasquirt, Megasquirt CAN protocol

MegaCAN_message_t respMsgMSC; // Stores response message back to Megasquirt, Megasquirt CAN protocol

MegaCAN_broadcast_message_t bCastMsg; // Stores unpacked Megasquirt broadcast data, e.g. bCastMsg.rpm

struct can_frame respMsg; // Actual response message back to Megasquirt, MSCAN protocol

uint16_t GPIOADC[8] = { 0 }; // Stores values to send to Megasquirt, 4 ADCS for each message

uint16_t adc0 = 0;

uint16_t adc1 = 0;

uint16_t adc2 = 0;

uint16_t adc3 = 0;

uint16_t adc4 = 0;

uint16_t adc5 = 0;

uint16_t adc6 = 0;

uint16_t adc7 = 0;

//Variables for averaging of sensor values

//AT

const int ATnumReadings = 10;

int ATreadings[ATnumReadings]; // The readings from the analog input

int ATreadIndex = 0; // The index of the current reading

int ATtotal = 0; // The running total

int ATaverage = 0; // The average

//OP

const int OPnumReadings = 10;

int OPreadings[OPnumReadings]; // The readings from the analog input

int OPreadIndex = 0; // The index of the current reading

int OPtotal = 0; // The running total

int OPaverage = 0; // The average

//FA

const int FAnumReadings = 100;

int FAreadings[FAnumReadings]; // The readings from the analog input

int FAreadIndex = 0; // The index of the current reading

int FAtotal = 0; // The running total

int FAaverage = 0; // The average

//FW

const int FWnumReadings = 100;

int FWreadings[FWnumReadings]; // The readings from the input

int FWreadIndex = 0; // The index of the current reading

int FWtotal = 0; // The running total

int FWaverage = 0; // The average

void initializeCAN() {

mcp2515.reset();

mcp2515.setBitrate(CAN_500KBPS, MCP_8MHZ); //Megasquirt specific 500kbs

mcp2515.setNormalMode();

}

void canMShandler(const can_frame &msg) {

// For Megasquirt CAN protocol, MS is requesting data:

if ((msg.can_id & CAN_EFF_FLAG) != 0) { //Data request from MS uses extended flag, there may be a better way to implement this with more advanced applications, works fine for sending data to MS GPIOADC

sendDataToMS(msg); //Due to the extended flag, we assume this is a MS data request and run the function to send data to MS, passing the message received from MS to the sendDataToMS function

}

// For Megasquirt CAN broadcast data:

else { //Broadcast data from MS does not use extended flag, therefore a standard message from MS will contain broadcast data

//Unpack megasquirt broadcast data into bCastMsg:

MegaCAN.getBCastData(msg.can_id, msg.data, bCastMsg); //baseID fixed in library based on const parameter entered for baseID above - converts the raw CAN id and buf to bCastMsg format

if (msg.can_id == finalID) {

/*~~~Final message for this batch of data, do stuff with the data - this is a simple example~~~*/

Serial.print(bCastMsg.map); Serial.print(" | "); //should be kPa

Serial.print(bCastMsg.rpm); Serial.print(" | "); //should be rpm

Serial.println(bCastMsg.tps); //should be %

}

}

}

void sendDataToMS(can_frame msg) {

MegaCAN.processMSreq(msg.can_id, msg.data, recMsgMSC); // Unpack request message ("msg") from MS into recMsgMS

// Create a bitmask for output states

uint16_t outputStates = 0;

outputStates |= (FCstatus << 0); // Bit 0: Fan Control

outputStates |= (ICSCstatus << 1); // Bit 1: IC Spray Control

outputStates |= (CSstatus << 2); // Bit 2: Camshaft Control

// Store outputStates in adc4

adc4 = outputStates;

if (recMsgMSC.core.toOffset == 2) { //For GPIOADC0-3

GPIOADC[0] = adc0; //Ambient Temperature

GPIOADC[1] = adc1; //Oil Pressure

GPIOADC[2] = adc2; //Fuel Amount

GPIOADC[3] = adc3; //Fuel Warning. ADC is not the best solution for an on/off, but will do

MegaCAN.setMSresp(recMsgMSC, respMsgMSC, GPIOADC[0], GPIOADC[1], GPIOADC[2], GPIOADC[3]); //Packs the GPIOADC0-3 values into "respMsgMSC"

}

else if (recMsgMSC.core.toOffset == 10) { //For GPIOADC4-7

GPIOADC[4] = adc4; //Output states

GPIOADC[5] = adc5; //vacant

GPIOADC[6] = adc6; //vacant

GPIOADC[7] = adc7; //vacant

MegaCAN.setMSresp(recMsgMSC, respMsgMSC, GPIOADC[4], GPIOADC[5], GPIOADC[6], GPIOADC[7]); //Packs the GPIOADC4-7 values into "respMsgMSC"

}

// Send response to Megasquirt using MSCAN protocol:

respMsg.can_id = respMsgMSC.responseCore | CAN_EFF_FLAG; //CAN_EFF_FLAG added to the end of response message, otherwise MS will not use it

respMsg.can_dlc = sizeof(respMsgMSC.data.response);

for (int i = 0; i < respMsg.can_dlc; i++) {

respMsg.data[i] = respMsgMSC.data.response[i];

}

mcp2515.sendMessage(&respMsg); //Sends the GPIOADC values stored in respMsg over CAN to Mesasquirt

//Serial.println("Data sent to Megasquirt");

}

void setup()

{

while (!Serial);

Serial.begin(115200);

Serial.println("MAP | RPM | TPS");

initializeCAN();

pinMode(33, INPUT); //Fuel warning indicator switch

pinMode(FCpin, OUTPUT); //Fan Control

pinMode(ICSCpin, OUTPUT); //Intercooler spray

pinMode(CSpin, OUTPUT); //Camshaft Control

digitalWrite(FCpin, LOW);

digitalWrite(ICSCpin, LOW);

digitalWrite(CSpin, LOW);

//Setup Ambient Temp readings

for (int ATthisReading = 0; ATthisReading < ATnumReadings; ATthisReading++) //As long as thisReading is smaller than numReadings, add to thisReading

{

ATreadings[ATthisReading] = 0;

}

AT.init(A2, 40); //Current from D40 and measuring voltage from A2

//Setup Oil Pressure readings

for (int OPthisReading = 0; OPthisReading < OPnumReadings; OPthisReading++) //As long as thisReading is smaller than numReadings, add to thisReading

{

OPreadings[OPthisReading] = 0;

}

OP.init(A0, 35); //Current from D35 and measuring voltage from A0

//Setup Fuel Amount readings

for (int FAthisReading = 0; FAthisReading < FAnumReadings; FAthisReading++) //As long as thisReading is smaller than numReadings, add to thisReading

{

FAreadings[FAthisReading] = 0;

}

FA.init(A1, 32); //Current from D32 and measuring voltage from A1

}

void loop() {

onReceived(); //Read messages from CAN-bus

getAT(); //Read Ambient Temperature and handle signal

getOP(); //Read Oil Pressure and handle signal

getFA(); //Read Fuel Amount and handle signal

getFW(); //Read Fuel Warning switch and handle signal

//Outputs

FanControl();

ICSControl();

CSControl();

output_test();

}

void onReceived()

//Listen to CAN-bus and run canMShandler after

{

if (mcp2515.readMessage(&receivedFrame) == MCP2515::ERROR_OK)

{

canMShandler(receivedFrame);

/*

Serial.println("Received message:");

Serial.println(" ID: 0x" + String(receivedFrame.can_id, HEX));

Serial.println(" DLC: " + String(receivedFrame.can_dlc));

Serial.println(" Data: " + String(receivedFrame.data[0]) + " " +

String(receivedFrame.data[1]) + " " +

String(receivedFrame.data[2]) + " " +

String(receivedFrame.data[3]) + " " +

String(receivedFrame.data[4]) + " " +

String(receivedFrame.data[5]) + " " +

String(receivedFrame.data[6]) + " " +

String(receivedFrame.data[7]));

*/

}

}

void getAT()

{

unsigned long ATcurrentMillis = millis(); // Record current time

if (ATcurrentMillis - ATlastExecutedMillis >= AT_EXE_INTERVAL) //If elapsed time from last execution is more than the specified interval

{

ATlastExecutedMillis = ATcurrentMillis; // save the last executed time

//AT

AT.measure(5, 1024, 10000, 3007, 3848, false); //float VCC,int _ADC, float R1, int R25, int Beta, bool prints

ATtotal = ATtotal - ATreadings[ATreadIndex]; // subtract the last reading

ATreadings[ATreadIndex] = AT.ambienttempvalue * 10; // read from the sensor

ATtotal = ATtotal + ATreadings[ATreadIndex]; // add the reading to the total

ATreadIndex = ATreadIndex + 1; // advance to the next position in the array

if (ATreadIndex >= ATnumReadings) // if we're at the end of the array...

{

ATreadIndex = 0; // ...wrap around to the beginning

}

ATaverage = ATtotal / ATnumReadings; // calculate the average

adc0 = ATaverage; // Insert average to variable adc0

//Serial.println(adc0);

}

}

void getOP()

{

unsigned long OPcurrentMillis = millis(); // Record current time

if (OPcurrentMillis - OPlastExecutedMillis >= OP_EXE_INTERVAL) //If elapsed time from last execution is more than the specified interval

{

OPlastExecutedMillis = OPcurrentMillis; // save the last executed time

//OP

OP.measure(5, 1024, 100, 10, 69, 129, 184, false); //float VCC, int _ADC, float R1, int R_0BAR, int R_1BAR, int R_2BAR, int R_3BAR, bool prints

OPtotal = OPtotal - OPreadings[OPreadIndex]; // subtract the last reading

OPreadings[OPreadIndex] = OP.oilpressurevalue * 100; // read from the sensor

OPtotal = OPtotal + OPreadings[OPreadIndex]; // add the reading to the total

OPreadIndex = OPreadIndex + 1; // advance to the next position in the array

if (OPreadIndex >= OPnumReadings) // if we're at the end of the array...

{

OPreadIndex = 0; // ...wrap around to the beginning:

}

OPaverage = OPtotal / OPnumReadings; // calculate the average

adc1 = OPaverage; // Insert average to variable adc1

//Serial.println(adc1);

}

}

void getFA()

{

unsigned long FAcurrentMillis = millis(); // Record current time

if (FAcurrentMillis - FAlastExecutedMillis >= FA_EXE_INTERVAL) //If elapsed time from last execution is more than the specified interval

{

FAlastExecutedMillis = FAcurrentMillis; // save the last executed time

//FA

FA.measure(5, 1024, 10, 2, 78, false); //float VCC,int _ADC, float R1, int R_Full, int R_Empty, bool prints

FAtotal = FAtotal - FAreadings[FAreadIndex]; // subtract the last reading

FAreadings[FAreadIndex] = FA.fuelamountvalue * 100; // read from the sensor

FAtotal = FAtotal + FAreadings[FAreadIndex]; // add the reading to the total

FAreadIndex = FAreadIndex + 1; // advance to the next position in the array

if (FAreadIndex >= FAnumReadings) // if we're at the end of the array...

{

FAreadIndex = 0; // ...wrap around to the beginning

}

FAaverage = FAtotal / FAnumReadings; // calculate the average

adc2 = FAaverage; // Insert average to variable adc2

//Serial.println(adc2);

}

}

void getFW()

{

unsigned long FWcurrentMillis = millis(); // Record current time

if (FWcurrentMillis - FWlastExecutedMillis >= FW_EXE_INTERVAL) //If elapsed time from last execution is more than the specified interval

{

FWlastExecutedMillis = FWcurrentMillis; // save the last executed time

//FW

FWtotal = FWtotal - FWreadings[FWreadIndex]; // subtract the last reading

int sensorVal = digitalRead(33); // read port status:

if (sensorVal = LOW) // If the switch is closed...

{

FWreadings[FWreadIndex] = 1; //...reading is one

}

else

{

FWreadings[FWreadIndex] = 0; //...reading is zero

}

FWtotal = FWtotal + FWreadings[FWreadIndex]; // add the reading to the total

FWreadIndex = FWreadIndex + 100; // advance to the next position in the array

// if we're at the end of the array...

if (FWreadIndex >= FWnumReadings)

{

FWreadIndex = 0; // ...wrap around to the beginning

}

FWaverage = FWtotal / FWnumReadings; // calculate the average

adc3 = FWaverage; // Insert average to variable adc3

//Serial.println(adc3);

}

}

void FanControl()

{

unsigned long FCcurrentMillis = millis(); // Record current time

if (FCcurrentMillis - FClastExecutedMillis >= FC_EXE_INTERVAL) //If elapsed time from last execution is more than the specified interval

{

FClastExecutedMillis = FCcurrentMillis;

if (((bCastMsg.tps >= 80 && bCastMsg.rpm <= 500) && output == 1) || (bCastMsg.clt-32)*5/9 >= 90 && FCstatus == 0)

{

if(FCstatus == 0){output = output + 1;}

digitalWrite(FCpin, HIGH);

Serial.println("Fan ON");

FCstatus = 1;

}

else if((bCastMsg.clt-32)*5/9 <= 87 && FCstatus == 1)

{

digitalWrite(FCpin, LOW);

Serial.println("Fan OFF");

FCstatus = 0;

}

//Serial.println((bCastMsg.clt-32)*5/9);

}

}

void ICSControl()

{

unsigned long ICSCcurrentMillis = millis(); // Record current time

if (ICSCcurrentMillis - ICSClastExecutedMillis >= ICSC_EXE_INTERVAL) //If elapsed time from last execution is more than the specified interval

{

ICSClastExecutedMillis = ICSCcurrentMillis;

//If throttle position is above 80 %, RPM below 500 (test mode)

//Or if throttle position is above 80 %, MAP above 150 kPa, IAT temperature more than 20°C above ambient

//Or if IAT temperature more than 30°C above ambient and speed more than 30 km/h and spray was last on more than 15s ago

if ((bCastMsg.tps >= 80 && bCastMsg.rpm <= 500) && output == 2 || (bCastMsg.tps >= 80 && bCastMsg.map >= 150 && (((bCastMsg.clt-32)*5/9)-(ATaverage/10)) >= 20) || ((((bCastMsg.clt-32)*5/9)-(ATaverage/10)) >= 30 && bCastMsg.gps_speed*3.6 > 30 && ICSCcurrentMillis - ICSCOnMillis >= 15000))

{

digitalWrite(ICSCpin, HIGH);

if(ICSCstatus == 0){output = output + 1;}

//Serial.println("IC Spray ON");

if(ICSCstatus == 0)

{

ICSCOnMillis = ICSCcurrentMillis;

ICSCstatus = 1;

}

}

else

{

digitalWrite(ICSCpin, LOW);

//Serial.println("IC Spray OFF");

}

if(ICSCcurrentMillis - ICSCOnMillis >= 3000)

{

digitalWrite(ICSCpin, LOW);

//Serial.println("IC Spray OFF");

ICSCstatus = 0;

}

}

}

void CSControl()

{

unsigned long CScurrentMillis = millis(); // Record current time

if (CScurrentMillis - CSlastExecutedMillis >= CS_EXE_INTERVAL) //If elapsed time from last execution is more than the specified interval

{

CSlastExecutedMillis = CScurrentMillis;

if (((bCastMsg.tps >= 80 && bCastMsg.rpm <= 500) && output == 3) || (bCastMsg.rpm >= 1500 && bCastMsg.rpm <= 4200 && CSstatus == 0))

{

if(CSstatus == 0){output = output + 1;}

digitalWrite(CSpin, HIGH);

Serial.println("Camshaft ON");

CSstatus = 1;

}

else if((bCastMsg.rpm <= 1450 || bCastMsg.rpm >= 4250) && CSstatus == 1)

{

digitalWrite(CSpin, LOW);

Serial.println("Camshaft OFF");

CSstatus = 0;

}

}

}

void output_test(){

if(output > 3)

{

output = 1;

}

}Näissä suurimpina muutoksina 3. ohjattava ulostulo ja se, että ulostulojen tilatieto lähetetään Megalle. Tilatieto ajetaan Arduinossa outputStates muuttujaan, joka menee adc4 muuttujana sitten CAN-väylään.

Koodi: Valitse kaikki

// Create a bitmask for output states

uint16_t outputStates = 0;

outputStates |= (FCstatus << 0); // Bit 0: Fan Control

outputStates |= (ICSCstatus << 1); // Bit 1: IC Spray Control

outputStates |= (CSstatus << 2); // Bit 2: Camshaft Control

// Store outputStates in adc4

adc4 = outputStates;Koodi: Valitse kaikki

CoolantFan = bits, U16, 112, [0:0]

InterCoolerSpray = bits, U16, 112, [1:1]

Camshaftontrol = bits, U16, 112, [2:2]Koodi: Valitse kaikki

entry = CoolantFan, "FanON", int, "%d"

entry = InterCoolerSpray, "ICSPrayON", int, "%d"

entry = Camshaftontrol, "CamshaftON", int, "%d"

Tuuletinta varten laitoin indikaattorin ja siihen kuvan, että näkee milloin tuuletin on päällä. Kuvassa testimoodi, eli kun kierrokset ovat alle 500 ja kaasunasento yli 80%, niin ulostuloja loopataan päälle.

To do lista tällä hetkellä:

- Korisarjan kiinnitykset kuntoon

- Ovien listojen kiinnitykset

- Ulkonäkö

- Takaikkunaa ympäröivien ruosteiden kiinniotto (ammattilaisella)

- (Ylimaalaus)

- Puskurien halkeamat kuntoon

- Antenni pois

- Konehuoneen maalaus/siistiminen

- Käyntihäiriön korjaus (alipainevuoto?)

- Ahtaminen

- Huohotuksen uudelleenreititys

- Muuta

- Olka-akselit ja jarrusatulat kiinni

- Penkitys

- Muutoskatsastus

Daily driver: Projekti, koska luotettavat autot ovat tylsiä Luotettava, eli tylsä CLK 270

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Entiset: W124 260E, W201 2.0, W201 2.0, S202 220 CDI

Projektina W201 M104 MS2 V3.0 Turbo

Pyhäajossa C126 560 SEC

Re: W201 2.0 8V -> 2.8 24V MS2 V3.0

Iso onnittelu leimasta ja todella hienosti toteutetusta paketista!

Harvoin näkee näin paljon ohjauksen koodia itse toteutettuna eikä vaan valmiiksi ostettuna!

Harvoin näkee näin paljon ohjauksen koodia itse toteutettuna eikä vaan valmiiksi ostettuna!